Service Hotline:

+86 13933297357

-

English

English

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

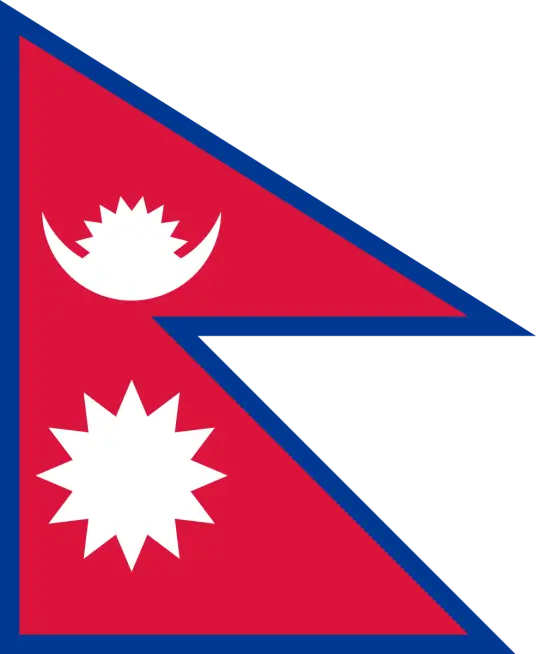

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

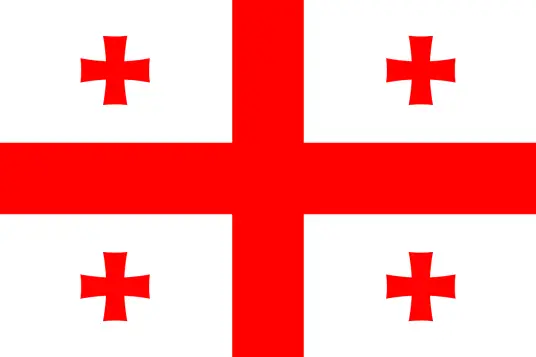

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

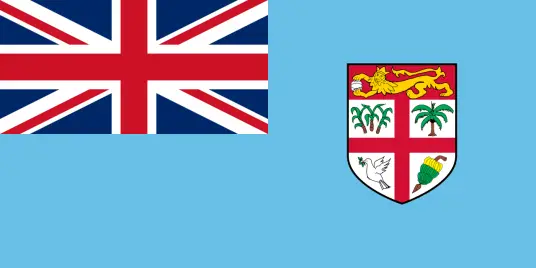

Fiji

Fiji

-

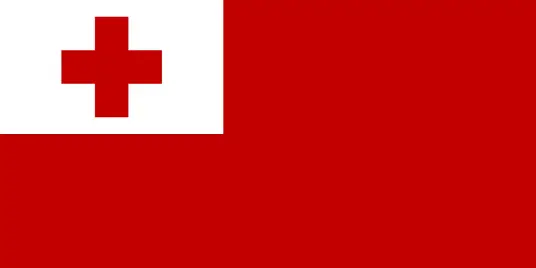

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

Whatsapp

Whatsapp Điện thoại

Điện thoại